Automatic Distributors for PPE, tools, equipment, stationery and keys

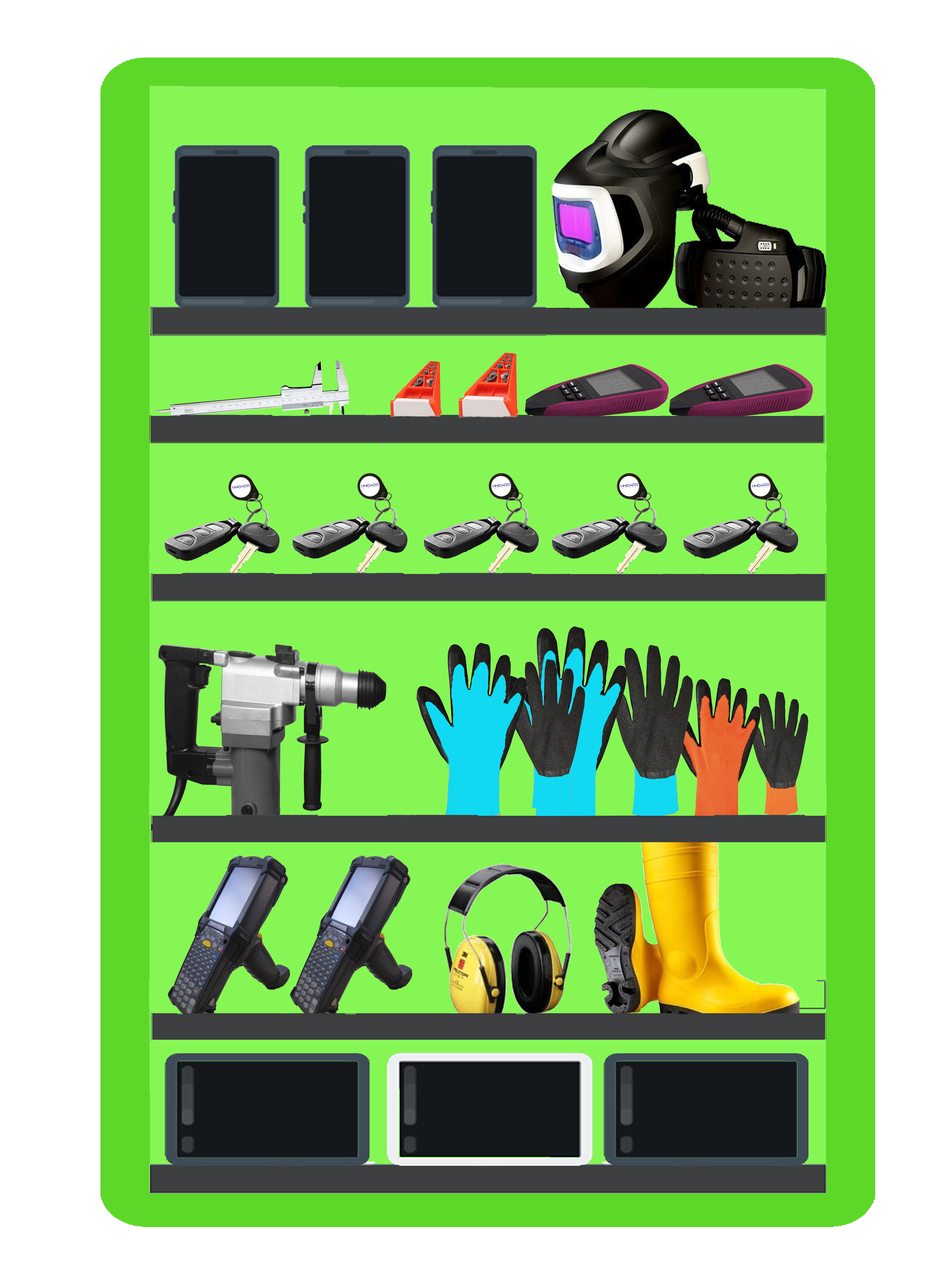

The Personal Storage Machines PSM, designed by Indaco Project, are automatic systems able to manage 24/7 the distribution and consumption of PPE - personal protective equipment - tools, equipment, fastening materials, stationery, keys and other items used daily in a company.

AUTOMATIC MANAGEMENT, DISTRIBUTION AND RETURN OF PPE AND VALUABLES

The industrial warehouses and automatic distributing equipment of Indaco Project streamline the internal logistic process starting from the loading of the distributors, items collection, delivery recording and certification, articles reordering, to the sending of alerts for the understock and stock of items;

They allow improvements, saving and reducing the objects consumption, reducing waste, tracking and recording movements according to current regulations on Security, Privacy and Waste management - R.E.N.T.R.I:

Automatic dispenser with sanization system- AK

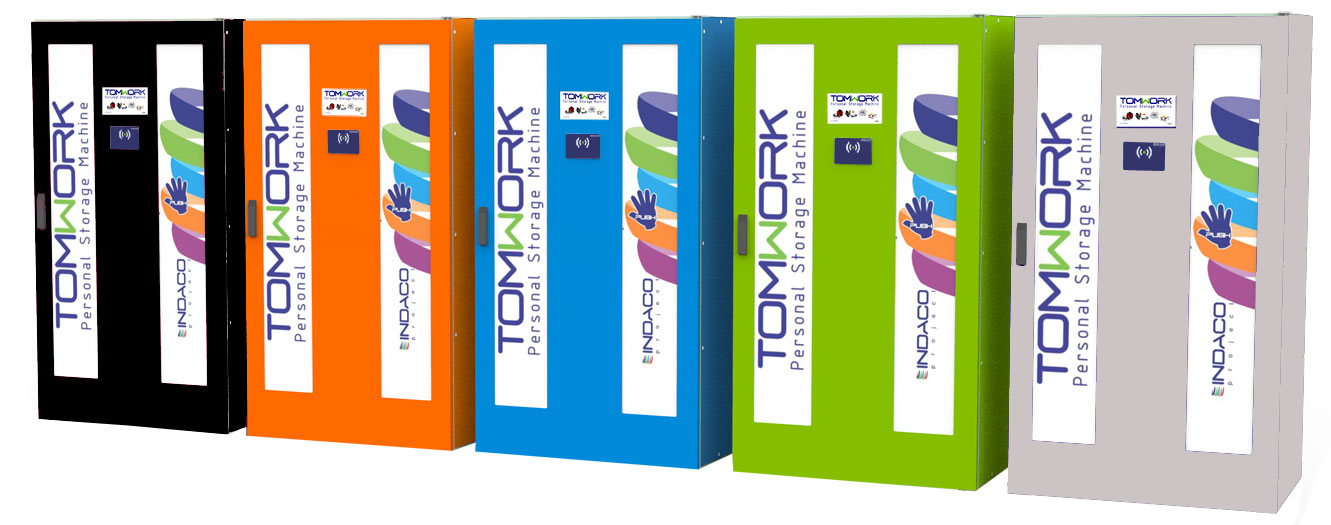

Automatic PPE distributor - TomWork

Smart Locker to manage large objects - BobLock

E-learning and PPE use instruction system - TC Consolle

Tracing, disposal, waste separate collection - Rosk

Automatic warehouse for tools, equipment and reusable items - TomWork+

Automatic warehouse for PPE and non-consumables - Tom3D

Automatic warehouse for tools, fastening and small parts - TomBox

Automatic distributor for keys and valuables - KeyCo

Manual Distribution Point for Large object with low turnover - PDM

Automatic Distributors for PPE, TomWork, TomWork+ are IECEE CB CERTIFIED

IECEE CB International Product Certification - with reference to the CB Scheme - is based on a multilateral agreement between EU countries and participating IECEE CB certification organizations in order to simplify and promote trade through the harmonization of standards on international basis.

This is an important acknowledgment for Indaco Project PSM systems - mainly for TomWork and TomWork+ - both for user safety and overall design and construction quality, in accordance with the standards recognized by EU countries and applicable to many non-EU countries.

INSTALLATION, TRAINING AND DIRECT SUPPORT

As manufacturer of PSM industrial distributing machines and software developers, we guide the customers from start-up to training sessions.

We grant after-sales support, so that our clients are always updated about correct use of products we supply safely.

PSM multi-product distributing machines can be purchased, leased or rented.

FOLLOW US IN THIS BRIEF ANALYSIS

What items do you have to handle with Automatic Distributing machines?

Personal Protective Equipment (PPE) PSM INDACO PROJECT: AK, TOMWORK, TOM3D, BOBLOCK, ROSK

Various consumables PSM INDACO PROJECT: AK, TOMWORK, TOM3D, BOBLOCK, ROSK

Tools INDACO PROJECT PSM: AK, TOMWORK+, TOM3D, BOBLOCK, TOMBOX, ROSK

Small equipment, fastening materials, components, inserts PSM INDACO PROJECT: TOM3D, BOBLOCK, TOMBOX, ROSK

Large objects and products PSM INDACO PROJECT: BOBLOCK, TOMBOX, PDM

Sets of keys for cars, forklifts, offices, hotel rooms PSM INDACO PROJECT: AK, KEYCO, TOM3D

Documents, Correspondence and Packages PSM INDACO PROJECT: BOBLOCK, TOMWORK+, PDM

Technological devices such as phones, PCs, tablets, keyboards, cables PSM INDACO PROJECT: TOMWORK+, TOM3D, BOBLOCK

DO YOU KNOW ALL THE ADVANTAGES of Indaco Project’s PSM?

HARDWARE AND SOFTWARE CUSTOMIZATION

Every company deserves its own PSM. One of the main strengths of the Personal Storage Machines is the possibility of customizing both hardware and software, allowing to manage a wide range of items with different sizes.

FUNCTIONALITY AND DESIGN – MADE IN ITALY

With INDACO PROJECT’s PSM, you are installing an efficient system as well as an industrial design element that become part and parcel of the company’s style and image. Everything is designed and manufactured in Italy.

BETTER ORGANIZATION

It is possible to set up different parameters (like minimum stock, withdrawal limits, etc.) that allow a deadline management and withdrawals checking of PPE and tools based on employees’ jobs. So stock management and demand monitoring are accurate and efficient, while the automation of the reordering process allows the system to send an email automatically to the supplier before stock reaches its minimum threshold.

COST SAVINGS

Indaco Project’s automatic distributors and storage systems can check and control real-time consumption, both in terms of withdrawals (picking) and warehouse (stock). They also track who withdraws what, how much, and for which work phase, while automatically managing maximum withdrawal limits for each operator.

Cost savings and reduction of PPE and tools usage will be among the first benefits: waste is reduced to zero and employees are gradually encouraged towards eco-friendly behavior.

TIME SAVINGS

The delivery and distribution time of items is drastically reduced thanks to the option of installing a vending machine at each workstation, minimizing the distance users must travel to reach the warehouse.

This eliminates queues at a single distribution point and avoids wasted time for all people involved in the process.

HOW TO START? ASK FOR A PROJECT PLANNING STUDY

Our Technical Team will find out the right configuration of PSM according to your company’s needs, after having analyzed work shifts, employee flow, type and dimensions of items to be manage.

Your company will get an immediate time saving, zero waste and zero production stops.