Automatic Distributor for PPE and Consumables – TOMWORK

Automatic Distributor: Increase Efficiency, Reduce Downtime and Costs, Improve Safety.

TomWork is the Automatic Industrial Distributor to manage PPE and consumables like:

• Personal Protective Equipment (PPE)

• Tools

• First aid items

• Solvents, Silicones, Paints and Glues

• Workwear and safety shoes

• Accessory and Stationary

TOMWORK FITS THE DEPARTMENT REQUEST

Industrial Automatic Distributors designed and produced by INDACO, like TOMWORK, are available in 3 different versions: 8, 10, and 12 levels.

Fully customizable internal configuration, which can additionally be changed over the time, serves the different consumption's requests of business departments. A New Technology that preserves the same high level of standard common to the PSM range and grants high level of safety at work.

MULTI-PICKING: Up to 12 items in one shot

TOMWORK multi-order picking function enhances the production reducing the downtime: user can choose and collect up to 12 items at in one shot. Thanks to the multi-picking, downtimes are reduced and withdrawal/return operations are speeded up.

Furthermore, thanks to Multiple Withdrawal, you can manage more items in a one kit, for example set for specific tasks, new hires, or visitors. If a disc stops, TomWork continues to work. Each plan has its own motor that allows it to work independently of the others. In this way, you reset downtime and always work in Safety.

New MUST-HAVE

• Triple capacity compared to standard Vending machines: storage capacity up to 852 different items

• Quick supply: max 3 second for picking

• Smart use of space: slots with double and triple heights for large items

• Max flexability: company can change the internal configuration autonomously based on consumption

• Automatic checking and recognition of discs configuration

TomWork - the advanced technology solution which grants security and high accuracy

TomWork can be combined with Rosk for waste disposal and with TC Consolle for continuous users training

TOMWORK Fast Access and Quick Distribution

- Each slot can manage a different item

- 36 different box sizes can be chosen

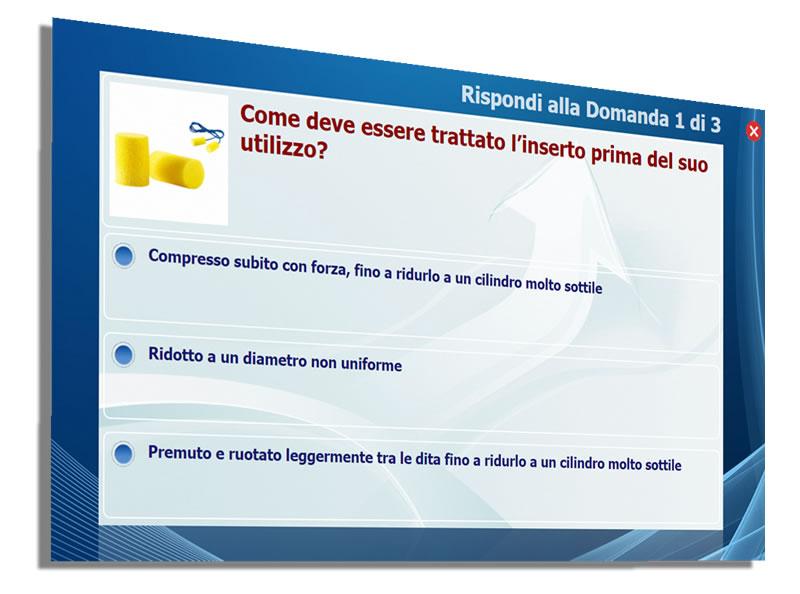

- Selection via touchscreen, with photo and description of items

- Multilingual voice guide

- Any kind of existing Company badge or Biometric reader can be used

- Self-diagnosis of operating state

- Recording of each withdrawal with date, time, job, user and further information

- Automatic checking of non-use or excessive use items

- Automatic reading of work orders with barcode

- Statistical analysis elaboration with automatic email transmission

- Stock management with automatic re-order to the supplier

- Deadlines management as per FIFO mode (First In First Out)

- Automatic alerts in case of tampering

- Custom reports generation

- 4.0 and 5.0 Compliance

- ERP integrations with software with API or other methods

CONSUMPTION CONTROL AND WASTE REDUCTION

• Product movement data registration

• Checking, consumption optimization and waste reduction

• Tracking of tools using-time and wear status

Product information request

PSM Systems

TC Consolle

We offer a reliable solution to meet mandatory training requirement on the correct use of PPE