TOMBOX DIGITAL KANBAN with user identification to manage the automatic distribution of tools and gears, fastening and other items

TomBox is an Automatic Warehouse with Digital Kanban that automates the dispensing and picking of small parts, fastening, cutting tools, gears and other items directly on site.

AUTOMATIC WAREHOUSE WITH USER IDENTIFICATION

Like the other INDACO Project Personal Storage Machines, TomBox requires the user identification before picking up or returning an item. However, with TOMBOX the user does not need to select the item on a screen, but can pick it up directly. Equipment records automatically which items and in what quantity are withdraw. In case of tampering, the system launch sound and visual alarms and can send an alert email to the supervisor.

TOMBOX Kanban Storage, speed up distribution process checking stock level

TOMBOX Key Features and Benefits

✓ Small floor space required

✓ Large storage capacity

✓ Customizable drawer configuration

✓ Different box sizes

✓ Everything available nearby your workstation

✓ Different size items can be managed

✓ Real-time checking of items used for any working process

Picking Up checking, withdrawal logging and user identification

Automatic detection of quantities withdrawn or deposited, thanks to load cells under each box

At least 30% reduction in consumption and 80% faster distribution and replenishment times

Improved planning of daily material needs for production lines and optimized processing workflows

Reliable statistics and accurate data about the items usage time as well as items method of use

Management of stock levels and understock, with automatic reorder notifications directly to suppliers

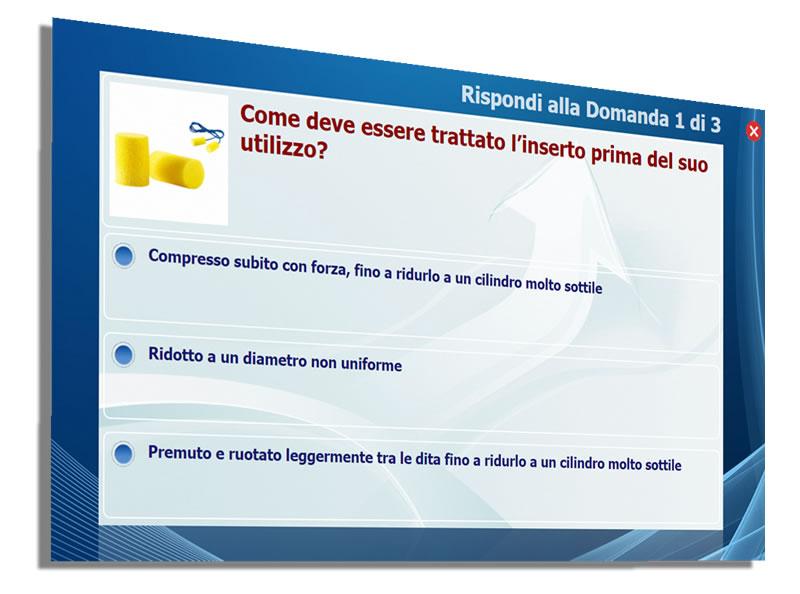

Integration with Rosk for items recycling management and TC console for e-learning on the proper use of PPE and equipment

Interface with ERP, stock management and safety systems

Product Information Request

PSM Systems

TC Consolle

We offer a reliable solution to meet mandatory training requirement on the correct use of PPE