Automatic Warehouse for PPE, tools and small parts

Automatic Distributor to manage Picking and Return of Reusable, Tools and PPE

TomWorkPlus is designed to manage, track and control the distribution of tools, equipment, measuring instruments, small parts and fastening, valuables and any other object used in a company.

TOMWORKPlus Key Features and Benefits

✓ 8, 10 or 12 discs with different capacity to satisfy customer needs

✓ Inside configuration can be changed over the time

✓ 24/7 Availability

✓ Items handled can have different size and weight

✓ Controlled and monitored dispensing

✓ Large capacity

✓ Customizable space in size and height

✓ Multi-order picking, up to 12 items in one shot

🟢 IECEE CB certified product

Certification issued by an International recognized institution.

🟢Collection and storage of multiple products with return reason declaration

🟢 80% Save Time both in distribution process and inventory stock control

🟢Automation of the complete items life-cycle management and checking of objects state of wear

🟢Statistic Analysis and accurate data regarding time and method of use of each item

🟢Management of stock and under-stock with reordering directly to the suppliers

🟢Integration with ROSK for waste management and e-learning TC consolle

🟢Interfacing with ERP, warehouse and security management

REGULATORY COMPLIANCE for a legally compliant company

REGULATORY COMPLIANCE for a legally compliant company

TOMWORKPlus enables companies to comply with Legislative Decree 81/08, OHSAS 18001, ISO 45001, and INAIL Safe Work Guidelines, thanks to:

• Recording and certification of the delivery of Personal Protective Equipment (PPE);

• Automatic alerts if an employee fails to withdraw the correct amount of PPE (as per the Risk Assessment Document - DVR) or does not withdraw any at all;

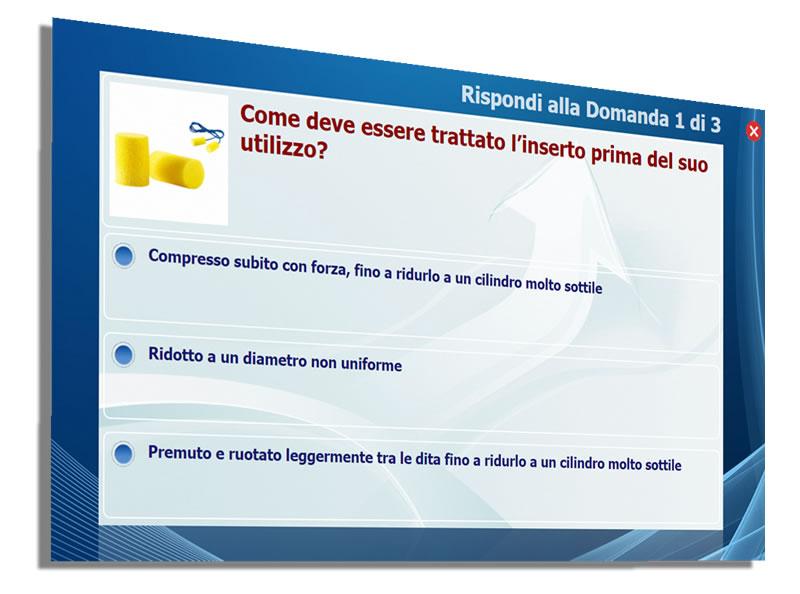

• Automatic enrollment in training courses about how to use PPE;

• PPE expiration management;

• Access restricted to only the tools allowed based on the job role, reducing the exposure risk to dangerous equipment.

SMART SELF-LEARNING, PICK UP and RETURN

TomWorkPlus is an IIoT (Industrial Internet of Things) system that stores and learns automatically: how many times an item has been picked up and then stored, for how long it was used; after how long it needs to be replaced; the most frequent reasons for the return being stopped....

Automating this process, the company can have a complete management of assets in real-time. Save time and reduce business costs. The method of returning item by reading the barcode code makes collection/return process faster and allows to avoid errors in repositioning the item inside the distributing machine.

In addition, the user’s interaction with the automatic tool warehouse TomWorkPlus is simplified thanks to the touchscreen monitor and multilingual voice guide: through personal badge or biometric system, the user can identifies himself and he is easily guided to the collection of the objects for which he is enabled.

SIMPLE HANDLING AND FAST PICKING

The MULTI-PICKING helps to speed up the object withdrawal. The user will take different items, organized in customized product KITS.

Customize TomWorkPlus according to your company’s needs

TomWorkPlus can be periodically reconfigured for different objects with different boxes size; Using the WEB software SESAMO Dispenser, you can easily assign new positions and spaces to items. Internal of TomWorkPlus can be modulated with boxes of different sizes both in width and height and, for large objects, it can be equipped with double or triple height discs.

TOMWORK+ is IECEE CB certified

Discover more: click here

Product Request information

PSM Systems

TC Consolle

We offer a reliable solution to meet mandatory training requirement on the correct use of PPE