Web Production Progress Control IN.DA.CO -

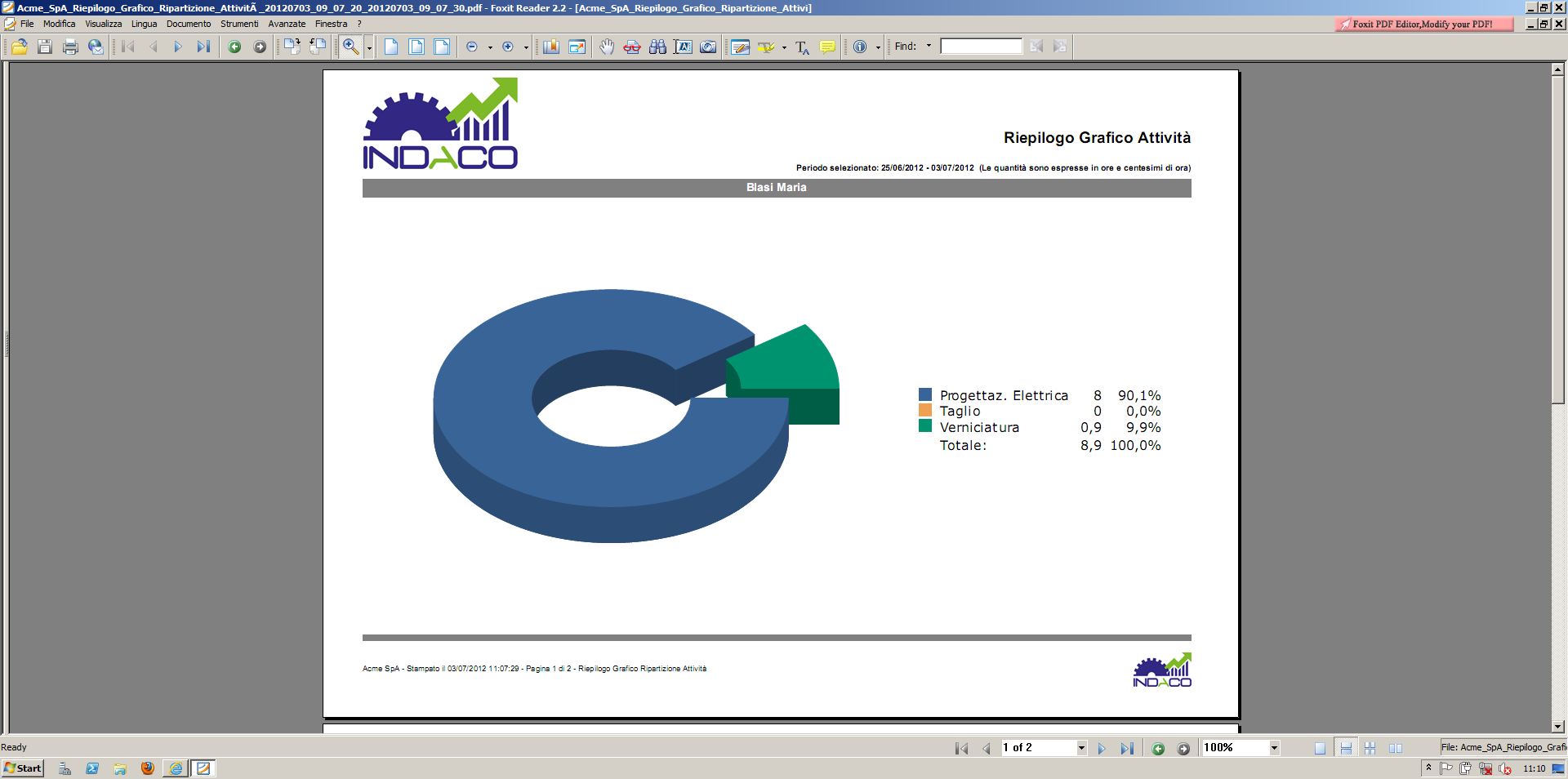

- The production time,

- The downtime (unproductiveness ) with relative reason,

- The produced quantities and the production wastes .

- The respect of the correct operative sequences foreseen by the production plan, in particular the correct declaration of the produced quantities

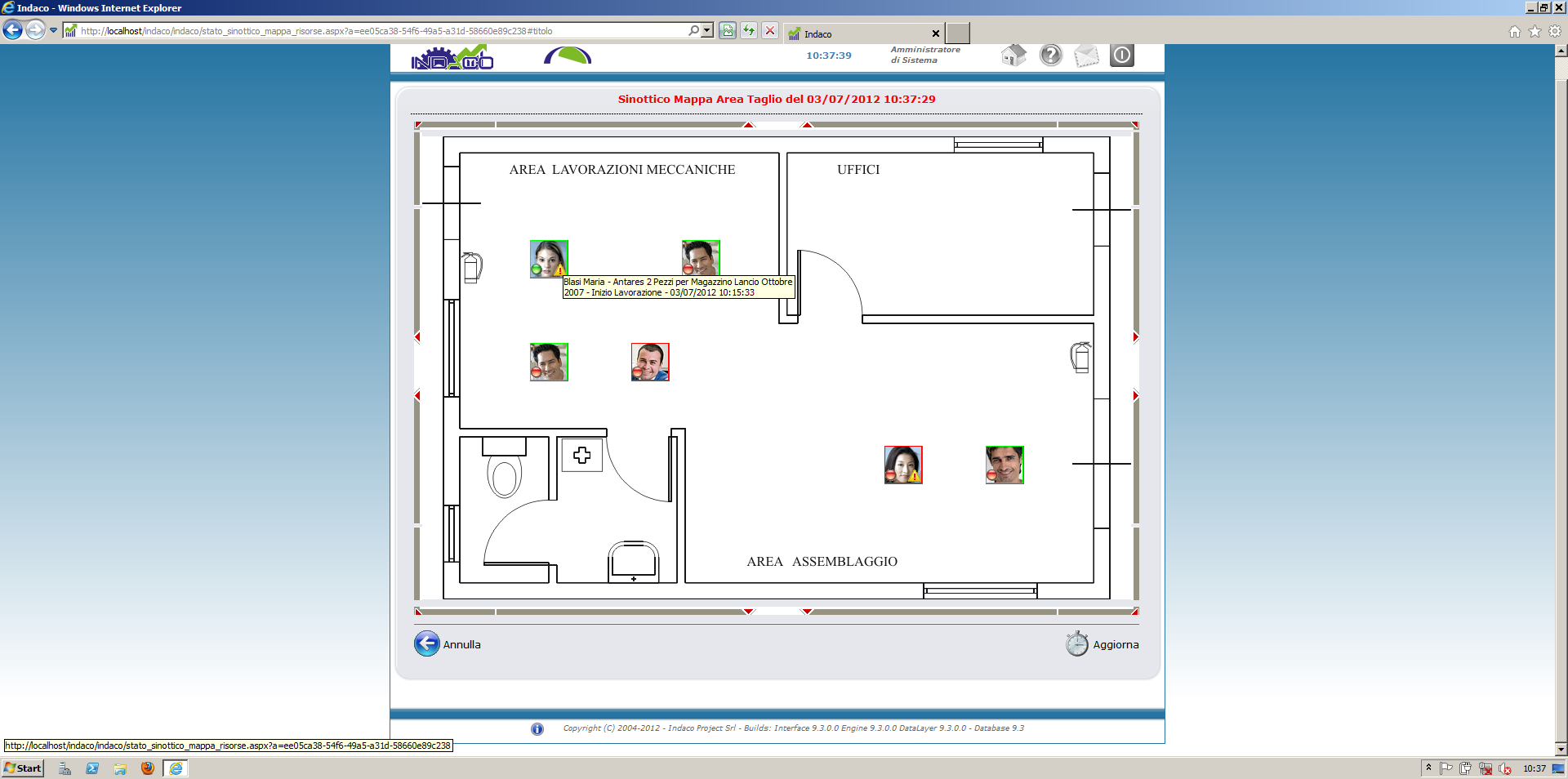

- The man/machine association for single working phase

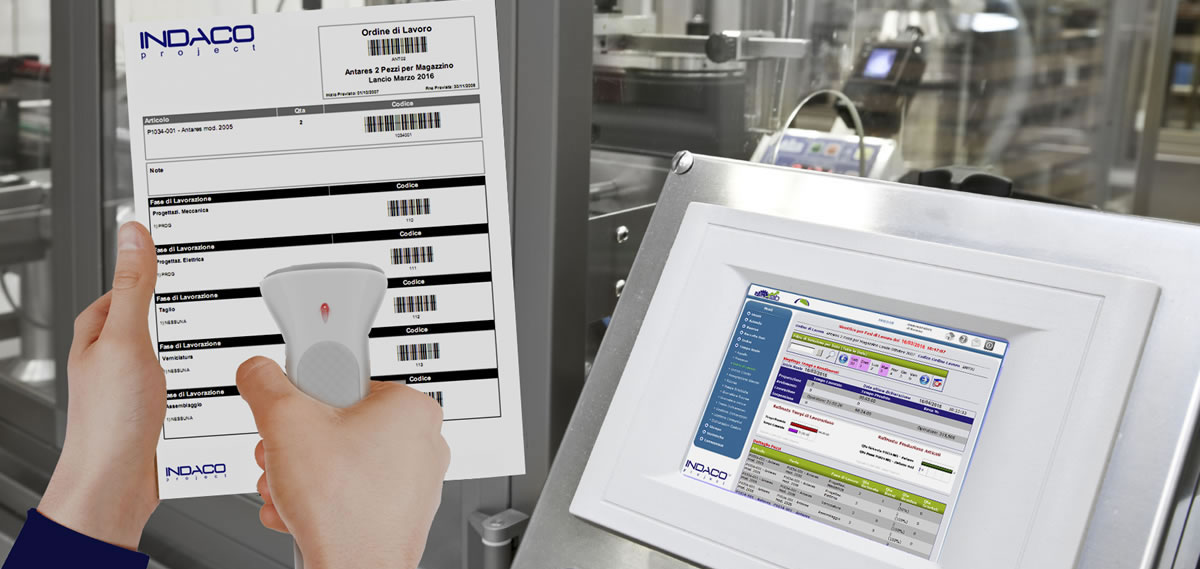

- The data collection takes place in real time and in a controlled manner.

- Each operator declares the activity and the machine on which he is operating, with the ability to create dynamically operator teams and to work at the same time on more phases, distributing the working hours automatically.

- The declaration is verified at the time of his registration in order to avoid every following necessity of management and to eliminate the time for correction of the incorrect declarations.

- The data are accessible from all the Pcs of the concern linked to intranet or

SYNOPTIC MAPS

- operators that carry out high level activities, or dealing with more tasks at the same time, and that cannot signal punctually every change of activity;

- concerns whose activity of production is composed both of internal and external phases, the external phases can be declared at closure;

- third-party workers, dealing only with a phase of the

An easy option allows the programme to send automatically the generated document to the selected mailbox, on fixed date and time. This allows the manager to control every morning the state of work developed on the previous day, without need to launch Indaco or sitting at his own pc.

Technical Characteristics

|

Architecture |

Web, based on Microsoft.NET Framework 4.0 and ASP.NET |

|

Required Web Server |

Microsoft IIS |

|

Compatibility of the operative Systems |

Microsoft Windows Server 2008, 2008 R2, 2012 |

|

Used Database |

Microsoft SQL Server 2008, 2008R2, 2012, 2014 |

|

Supported Client-side Browsers |

Microsoft Internet Explorer or higher, Mozilla FireFox 4 or higher, Opera 10 or higher |

|

Screen Resolution |

min. Client-side 1024 x 768 pixel |

|

Disc space |

Typical used server-side 2 GB |

|

|

|